English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

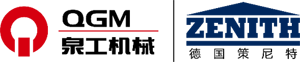

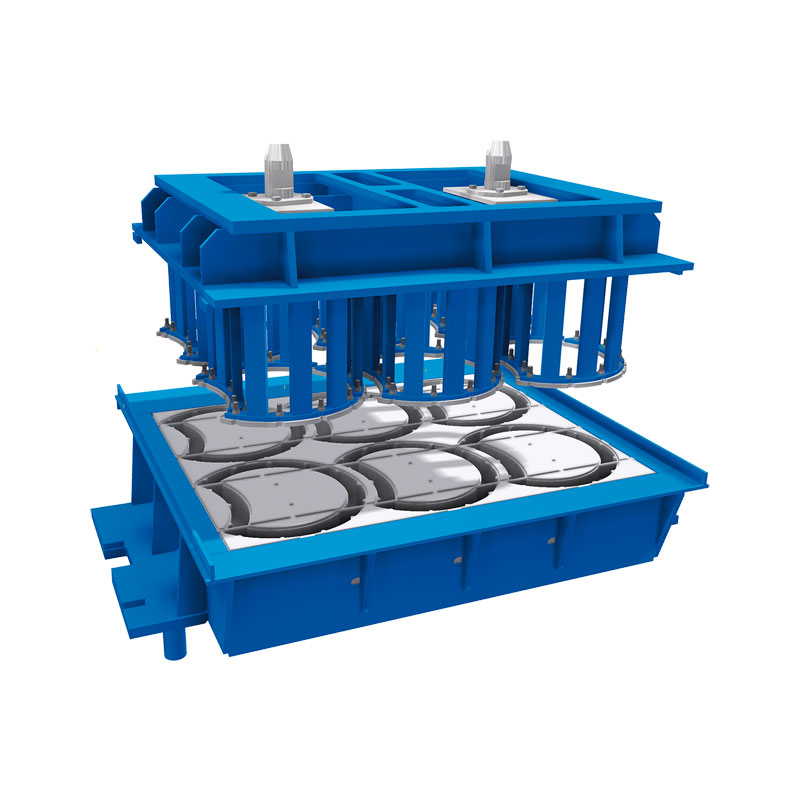

Paver pwm

Xa lus nug

Raws li cov chaw tsim khoom lag luam, peb xav muab Paver Mould rau koj. QGM paver pwm txais cov pa roj carbon tsawg tsawg siab lub zog carburizing hlau thiab sib txuas cov xov hlau txiav cov cuab yeej siv high-precision CNC ua technolbgy thiab 3D scanning thev naus laus zis los muab cov neeg siv khoom nrog pwm customization. Cov thev naus laus zis no tuaj yeem tsim qhov tsis zoo ntawm contours thiab geometric duab.Nws tshem tawm ntawm 0.3-0.4mm, nrog cov kab ntsug ntsug thiab cov: lub ntsej muag lub ntsej muag. Pavers tsim los ntawm QGM yog qhov yooj yim-demoulding, siab precision, tsis muaj burrs nyob ib ncig ntawm. Moulds tuaj yeem paub cov qauv tsim qauv thiab cov phaj siab sib hloov tsim.

Txhawm rau ua kom cov pwm ua haujlwm tau ntev, QGM paver pwm txais kev kho mob carbunizing., pwm framies thiab cov phaj siab yog hardened 60-63HRC, thiab mirnimuim hardening qhov tob yog 1.2m.Raws li cov neeg siv khoom thov, pwm tuaj yeem tsim thiab tsim los ntawm vuam lossis modular xov xauv.

Peb muab cov khoom zoo Paver Moulds rau txhua hom tshuab thiab cov cuab yeej fittings hauv cov qauv hauv qab no:

A) Mould tsim nplaim taws txiav

Nqaim web thicknesses ua tau

Optimal exploitation ntawm pwm

Tshuab dependent stamp khau clearance ntawm 0.2-0.5 hli

Counter-conical sab phab ntsa ua tau

Tsis muaj tuav grooves tsim nyog

Hom tsim rau multilayer ntau lawm machinery

Optional rho daim ntawv tsim

Los ntawm digitalization dawb nto tsim realizable

Heatable stamp khau tsim siv tau

B) MULD DESIGN MILLED

Muaj feem xyuam rau tag nrho cov contours thiab geometries

Tolerances hauv lub thawv pwm hauv qab +/- 0.3 hli

Tshuab dependent stamp khau clearance ntawm 0.2-0.5 hli

Precise ntsug, angled thiab du phab ntsa

Yooj yim demoulding

High precision ntawm haum

Qhov chaw tuav hauv txhua qhov tsim tau ua tau

Optional rho daim ntawv tsim

Los ntawm digitalization dawb nto tsim realizable

Heatable stamp khau tsim siv tau

Hnav tiv thaiv rau tag nrho cov pavement pwm raws li hauv qab no:

A) CARBURIZING (62-68 HRC)

Pwm lub thawv thiab cov khau khau tawv tawv (62-68 HRC)

Hardness nkag mus min. 1, 2 mm

B) NITRATING (62-68 HRC)

Pwm lub thawv thiab cov khau khiab khau khiab (62-68 HRC)

Hardness nkag mus min. 0,4mm ib

Tsis tshua muaj kev ntxhov siab sab hauv piv rau cov pwm kho los ntawm carburizing

Pom zoo rau me me web thicknesses

Siab contour raug tshaj pwm kho los ntawm carburizing

Ua raws li cov kev xav tau los ntawm cov neeg siv khoom, peb cov pwm tuaj yeem tsim thiab tsim nyob rau hauv weld lossis modular ntsia hlau xov xauv txoj kev.